Reviewed by Tamir Rubin, Head of Product at iPREP • Updated January 2026

ASE A1 Sample Question

A customer brings in their car complaining of a rough idle. You notice that the Check Engine Light is on and retrieve a P0302 code. What does this code indicate?

- A problem with the fuel injector

- A misfire in cylinder 3

- A problem with the oxygen sensor

- A misfire in cylinder 2

A1 – Engine Repair

60 questions • 75 minutes

- Diagnose mechanical engine condition problems

- Interpret compression and leak-down results

- Select appropriate cylinder head repair actions

- Evaluate lubrication and cooling system faults

A2 – Automatic Transmission/Transaxle

60 questions • 75 minutes

- Diagnose shift concerns with scan data

- Interpret pressure tests and fluid condition

- Identify electronic control component failures

- Select in-vehicle and bench repairs

A3 – Manual Drive Train and Axles

50 questions • 60 minutes

- Diagnose clutch, gearbox, and driveline issues

- Evaluate axles, differentials, and bearings

- Interpret noise, vibration, and wear signs

- Select adjustment and replacement procedures

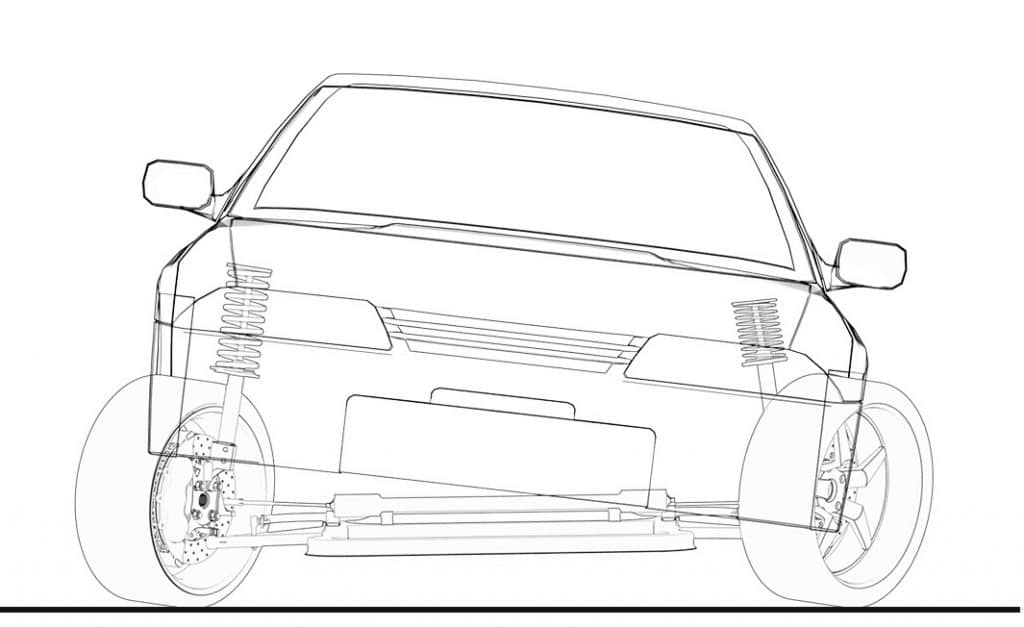

A4 – Suspension and Steering

50 questions • 60 minutes

- Diagnose steering pull and wander symptoms

- Evaluate suspension parts and alignment data

- Interpret tire wear and handling cues

- Select repairs for shocks and joints

A5 – Brakes

55 questions • 75 minutes

- Diagnose hydraulic and ABS brake faults

- Interpret pedal feel and stopping issues

- Evaluate rotors, drums, and friction wear

- Select safe service procedures and parts

A6 – Electrical/Electronic Systems

60 questions • 90 minutes

- Diagnose electrical faults using test tools

- Interpret wiring diagrams and circuit readings

- Identify sensor, module, and network issues

- Select repairs for starting and charging

A7 – Heating and Air Conditioning

60 questions • 75 minutes

- Diagnose HVAC performance and comfort issues

- Interpret pressures and temperature split readings

- Identify leaks, compressors, and control faults

- Select repairs for airflow distribution problems

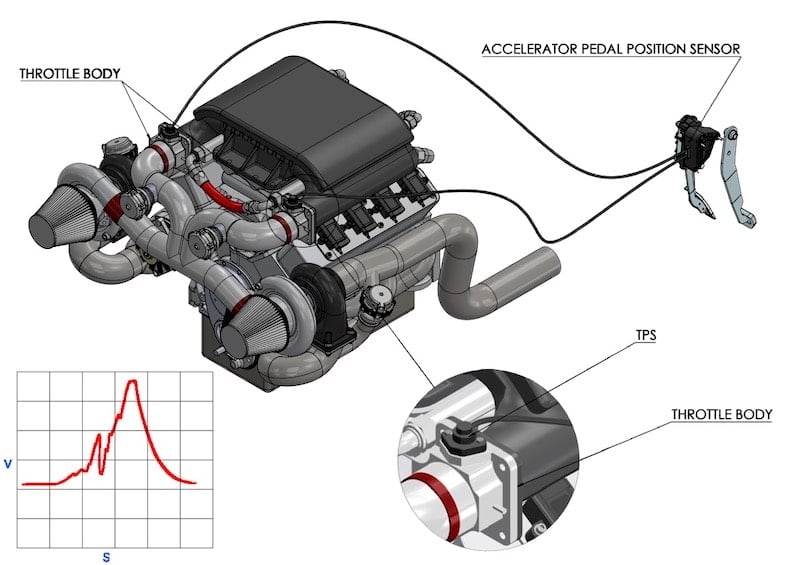

A8 – Engine Performance

60 questions • 75 minutes

- Diagnose drivability and emissions complaints

- Interpret scan data and sensor signals

- Evaluate fuel, ignition, and air systems

- Select next diagnostic step and repair

Test Duration

Total time: typically 60–90 minutes per A-test.

Plan your pacing by A-test, not overall. Research questions are mixed in and timed the same as scored questions, so practice completing a full set within the posted time limit.

Test Breakdown & Sample Questions

| Test Series | Description |

|---|---|

| A1 – Engine Repair | Covers engine repair skills |

| A2 – Automatic Transmission/Transaxle | Covers automatic transmission and transaxle skills |

| A3 – Manual Drive Train and Axles | Covers manual drive train and axles skills |

| A4 – Suspension and Steering | Covers suspension and steering skills |

| A5 – Brakes | Covers brake system skills |

| A6 – Electrical/Electronic Systems | Covers electrical and electronic systems skills |

| A7 – Heating and Air Conditioning | Covers heating and air conditioning skills |

| A8 – Engine Performance | Covers engine performance skills |

Each Automobile (A-series) certification test uses multiple-choice questions built around real shop situations—verifying concerns, interpreting test results, diagnosing faults, and selecting the correct repair. Certification tests include 10 additional research questions that do not count toward your score. Since you won’t know which ones are research questions, plan to answer every question.

| Test | Name | Number of Certification Test Questions | Certification Test Time | Number of Recertification Test Questions | Recertification Test Time |

|---|---|---|---|---|---|

| A1 | Engine Repair | 60 total / 50 scored* | 75 mins | 25 | 30 mins |

| A2 | Automatic Transmission / Transaxle | 60 total / 50 scored* | 75 mins | 25 | 30 mins |

| A3 | Manual Drive Train and Axles | 50 total / 40 scored* | 60 mins | 20 | 30 mins |

| A4 | Suspension and Steering | 50 total / 40 scored* | 60 mins | 20 | 30 mins |

| A5 | Brakes | 55 total / 45 scored* | 75 mins | 23 | 30 mins |

| A6 | Electrical / Electronic Systems | 60 total / 50 scored* | 90 mins | 25 | 45 mins |

| A7 | Heating and Air Conditioning | 60 total / 50 scored* | 75 mins | 25 | 30 mins |

| A8 | Engine Performance | 60 total / 50 scored* | 75 mins | 25 | 45 mins |

*Note: Each certification test includes 10 research questions that do not contribute to the final score. Because it’s not clear which questions are research questions, it’s important to answer all questions. To be eligible for the shorter recertification test, you must have previously passed the certification test.

A1 – Engine Repair Test

A1 (Engine Repair) is part of the ASE Automobile (A-series) certification program and counts toward Master Automobile Technician status (with A1–A8). It focuses on diagnosing engine mechanical concerns and choosing the correct repair or service action.

The test includes 60 multiple-choice questions (50 scored plus 10 research questions) and has a 75-minute time limit.

A1 covers: general engine diagnosis and condition testing, cylinder head/valve train diagnosis and repair, engine block diagnosis and repair, lubrication/cooling system diagnosis and repair, and related inspection/service items that support engine repair.

A1 Sample Question

A customer complains of a high-pitched squealing noise coming from the engine compartment that increases in frequency as the engine speed increases. The MOST likely cause of this noise is:

- A failing water pump.

- A loose or worn drive belt.

- A malfunctioning power steering pump.

- A clogged fuel injector.

Answer: B. A loose or worn drive belt.

Explanation:

A high-pitched squealing noise that increases with engine speed is most commonly associated with a loose or worn drive belt (Answer B). When the belt slips on the pulleys, it can produce a squealing noise.

Answer A is incorrect because a failing water pump typically causes a grinding or growling noise, not a high-pitched squeal.

Answer C is incorrect because a malfunctioning power steering pump usually causes a whining noise, especially when turning the steering wheel, not a squeal that increases with engine speed.

Answer D is incorrect because a clogged fuel injector would affect engine performance and might cause a misfire or rough idle, but it wouldn’t cause a squealing noise.

A2 – Automatic Transmission/Transaxle Test

A2 (Automatic Transmission/Transaxle) is part of the ASE Automobile (A-series) certification program and counts toward Master Automobile Technician status (with A1–A8). It focuses on diagnosing automatic transmission/transaxle concerns and selecting the correct repair or service action.

The test includes 60 multiple-choice questions (50 scored plus 10 research questions) and has a 75-minute time limit.

A2 covers: general transmission/transaxle diagnosis (including electronic controls), in-vehicle maintenance and repair, and off-vehicle repair, with common real-world scenarios involving scan-tool data, shift concerns, fluid/pressure checks, and modern designs such as CVT and dual-clutch systems.

A2 Sample Question

A vehicle with an automatic transmission is not shifting into third gear. The fluid level is correct and the fluid is not burnt. The MOST likely cause of this problem is:

- A worn clutch disc.

- A faulty shift solenoid.

- A clogged fuel filter.

- A malfunctioning engine temperature sensor.

Answer: B. A faulty shift solenoid.

Explanation:

Automatic transmissions use shift solenoids to control the flow of hydraulic fluid for shifting. If a vehicle is not shifting into a particular gear, a faulty shift solenoid (Answer B) is a likely cause.

Answer A is incorrect because automatic transmissions do not use a clutch disc. This is a component found in manual transmissions.

Answer C is incorrect because a clogged fuel filter would typically cause engine performance problems, not specific transmission shifting issues.

Answer D is incorrect because while a malfunctioning engine temperature sensor can cause various issues, it is not typically associated with a transmission failing to shift into a specific gear.

A3 – Manual Drive Train and Axles Test

A3 (Manual Drive Train and Axles) is part of the ASE Automobile (A-series) certification program and counts toward Master Automobile Technician status (with A1–A8). It focuses on diagnosing manual driveline concerns and selecting the correct repair or service action.

The test includes 50 multiple-choice questions (40 scored plus 10 research questions) and has a 60-minute time limit.

A3 covers: clutch diagnosis and repair, manual transmission/transaxle concerns, driveshaft/half-shaft and CV joint issues, differential/final drive operation, and related inspections, measurements, and service procedures.

A3 Sample Question

A vehicle with a manual transmission pops out of first gear shortly after being engaged. The transmission fluid level is correct and the fluid is not burnt. The MOST likely cause of this problem is:

- A worn first gear synchronizer.

- A faulty clutch master cylinder.

- A clogged fuel filter.

- A malfunctioning engine temperature sensor.

Answer: A. A worn first gear synchronizer.

Explanation:

Manual transmissions use synchronizers to smoothly engage the gears. If a vehicle pops out of first gear shortly after being engaged, a worn first gear synchronizer (Answer A) is a likely cause.

Answer B is incorrect because a faulty clutch master cylinder would typically cause difficulty in shifting gears, not the transmission popping out of a specific gear.

Answer C is incorrect because a clogged fuel filter would typically cause engine performance problems, not specific transmission shifting issues.

Answer D is incorrect because while a malfunctioning engine temperature sensor can cause various issues, it is not typically associated with a transmission popping out of a specific gear.

A4 – Suspension and Steering Test

A4 (Suspension and Steering) is part of the ASE Automobile (A-series) certification program and counts toward Master Automobile Technician status (with A1–A8). It focuses on diagnosing steering and suspension concerns and selecting the correct repair or service action.

The test includes 50 multiple-choice questions (40 scored plus 10 research questions) and has a 60-minute time limit.

A4 covers: steering system diagnosis and repair, suspension diagnosis and repair, wheel alignment basics (diagnosis and correction), and wheel/tire concerns using inspections, measurements, and safe service procedures.

A4 Sample Question

A vehicle pulls to the right when the brakes are applied. The brake system has been inspected and no faults were found. The MOST likely cause of this problem is:

- A worn left front wheel bearing.

- A faulty power steering pump.

- An underinflated right front tire.

- A clogged fuel injector.

Answer: C. An underinflated right front tire.

Explanation:

If a vehicle pulls to one side when the brakes are applied and no faults are found in the brake system, a tire issue is a likely cause. An underinflated tire (Answer C) on the side the vehicle is pulling towards can cause this symptom.

Answer A is incorrect because a worn wheel bearing would typically cause a rumbling noise and possibly play in the wheel, but it wouldn’t typically cause the vehicle to pull to one side when braking.

Answer B is incorrect because a faulty power steering pump would typically cause difficulty in steering or a whining noise, not a pull to one side when braking.

Answer D is incorrect because a clogged fuel injector would typically cause engine performance problems, not a pull to one side when braking.

A5 – Brakes Test

A5 (Brakes) is part of the ASE Automobile (A-series) certification program and counts toward Master Automobile Technician status (with A1–A8). It focuses on diagnosing brake system concerns and selecting the correct repair or service action.

The test includes 55 multiple-choice questions (45 scored plus 10 research questions) and has a 75-minute time limit.

A5 covers: hydraulic system diagnosis, disc and drum brake service, power assist components, ABS operation and diagnosis, parking brake concerns, and safe inspection/testing procedures used to confirm the cause of a brake complaint.

A5 Sample Question

A vehicle’s brake pedal feels spongy and the brake fluid level in the master cylinder is correct. The MOST likely cause of this problem is:

- Air in the brake lines.

- A worn brake pad.

- A faulty power steering pump.

- A clogged fuel filter.

Answer: A. Air in the brake lines.

Explanation:

A spongy brake pedal is often caused by air in the brake lines (Answer A). Air in the hydraulic system of the brakes can compress, unlike the brake fluid, which leads to a spongy or soft brake pedal feel.

Answer B is incorrect because worn brake pads would typically cause a decrease in braking performance or a squealing noise, not a spongy brake pedal.

Answer C is incorrect because a faulty power steering pump would typically cause steering-related problems, not a spongy brake pedal.

Answer D is incorrect because a clogged fuel filter would typically cause engine performance problems, not a spongy brake pedal.

A6 – Electrical/Electronic Systems Test

A6 (Electrical/Electronic Systems) is part of the ASE Automobile (A-series) certification program and counts toward Master Automobile Technician status (with A1–A8). It focuses on diagnosing electrical/electronic concerns and selecting the correct repair or service action.

The test includes 60 multiple-choice questions (50 scored plus 10 research questions) and has a 90-minute time limit.

A6 covers: general electrical diagnosis, wiring/circuit testing, starting and charging systems, battery concerns, lighting and accessories, and electronic controls using wiring diagrams plus test tools such as a DMM and scan tool.

A6 Sample Question

A vehicle’s battery drains overnight. All lights are turned off and no obvious electrical devices are left on. The MOST likely cause of this problem is:

- A faulty alternator.

- A parasitic draw.

- A worn serpentine belt.

- A clogged fuel filter.

Answer: B. A parasitic draw.

Explanation:

If a vehicle’s battery drains overnight with no obvious electrical devices left on, the most likely cause is a parasitic draw (Answer B). This is when an electrical device continues to use power from the battery even after the vehicle is turned off.

Answer A is incorrect because a faulty alternator would typically cause the battery to drain while the vehicle is running, not when it’s turned off.

Answer C is incorrect because a worn serpentine belt would typically cause issues with the operation of the alternator, power steering pump, or air conditioning compressor, but it wouldn’t cause the battery to drain overnight.

Answer D is incorrect because a clogged fuel filter would typically cause engine performance problems, not a battery drain.

A7 – Heating and Air Conditioning Test

A7 (Heating and Air Conditioning) is part of the ASE Automobile (A-series) certification program and counts toward Master Automobile Technician status (with A1–A8). It focuses on diagnosing HVAC concerns and selecting the correct repair or service action.

The test includes 60 multiple-choice questions (50 scored plus 10 research questions) and has a 75-minute time limit.

A7 covers: A/C and heating system performance concerns, refrigeration components, air distribution and blower controls, engine cooling/heat delivery issues that affect cabin heat, and diagnosis of system controls using safe, correct service procedures.

A7 Sample Question

A vehicle’s air conditioning system is not cooling effectively. The compressor is engaging and the system is properly charged with refrigerant. The MOST likely cause of this problem is:

- A faulty thermostat.

- A clogged condenser.

- A worn serpentine belt.

- A clogged fuel filter.

Answer: B. A clogged condenser.

Explanation:

If a vehicle’s air conditioning system is not cooling effectively, but the compressor is engaging and the system is properly charged, the most likely cause is a clogged condenser (Answer B). The condenser’s job is to expel heat from the refrigerant. If it’s clogged, it can’t effectively cool the refrigerant, which leads to poor cooling performance.

Answer A is incorrect because a faulty thermostat would typically cause engine temperature problems, not issues with the air conditioning system.

Answer C is incorrect because a worn serpentine belt could cause the compressor to not operate effectively, but in this case, the compressor is engaging properly.

Answer D is incorrect because a clogged fuel filter would typically cause engine performance problems, not issues with the air conditioning system.

A8 – Engine Performance Test

A8 (Engine Performance) is part of the ASE Automobile (A-series) certification program and counts toward Master Automobile Technician status (with A1–A8). It focuses on diagnosing drivability and emissions-related concerns and selecting the correct repair or service action.

The test includes 60 multiple-choice questions (50 scored plus 10 research questions) and has a 75-minute time limit.

A8 covers: engine performance diagnosis, ignition and fuel control, air induction and exhaust, emissions/EVAP-related concerns, sensors/actuators and PCM inputs/outputs, and scan-tool-based diagnosis using a logical troubleshooting approach.

A8 Sample Question

A vehicle has poor fuel economy and the check engine light is on. The scan tool shows a code for a lean condition. The MOST likely cause of this problem is:

- A faulty spark plug.

- A clogged fuel injector.

- A worn serpentine belt.

- A leaking intake manifold gasket.

Answer: D. A leaking intake manifold gasket.

Explanation:

A lean condition means there is too much air and not enough fuel in the air-fuel mixture. This can be caused by a leak in the intake manifold gasket (Answer D), which allows extra air to enter the engine. This can lead to poor fuel economy and trigger the check engine light.

Answer A is incorrect because a faulty spark plug would typically cause a misfire or rough idle, not a lean condition.

Answer B is incorrect because a clogged fuel injector can cause a lean condition, but it would typically also cause a misfire or rough idle, not just poor fuel economy and a check engine light.

Answer C is incorrect because a worn serpentine belt would typically cause issues with the operation of the alternator, power steering pump, or air conditioning compressor, but it wouldn’t cause a lean condition.

Did you know?

The ASE A1–A8 Automobile exams are computer-based, multiple-choice tests based on real shop diagnostics; ASE certification typically requires two years of hands-on experience (or an approved mix of training and work), results are reported as pass/fail on a scaled system, and many employers use ASE credentials as a trusted benchmark for hiring and promotion.

Preparation Strategies

Preparing for the ASE Certification Test is a significant undertaking that benefits from a clear, structured plan. The A1–A8 exams don’t just test recall—they measure how well you understand automotive systems and apply diagnostic logic to real-world scenarios. Use these strategies to prepare effectively:

Understand the test structure: Review what each A-test (A1–A8) covers so you can plan your study time and avoid surprises on exam day.

Use the official ASE study guides: Start with the official content outlines to understand what’s tested, then use sample questions to learn how ASE asks about those topics.

Build hands-on confidence: Whenever possible, connect study topics to real shop work—especially test procedures, symptom verification, and interpreting results.

Study consistently: Set a weekly schedule and spread preparation over time. Short, repeated study sessions typically work better than last-minute cramming.

Choose up-to-date materials: Use resources aligned to the current A1–A8 objectives and avoid outdated references that may miss modern systems and diagnostic expectations.

Practice with sample questions: Treat practice questions as skill-building: identify what the question is really asking, eliminate distractors, and learn from each explanation.

Take care of your basics: Sleep, nutrition, and stress management matter—especially when you’re balancing work and studying.

Stay confident and focused: Measure progress by what you can diagnose and explain, not just what you can memorize. The goal is to pass—and to strengthen the skills you’ll use on the job.

Test Features

Purpose of the ASE Certification Test

The ASE Certification Test is designed to measure the skills and knowledge of automotive service professionals. Its primary purpose is to verify that technicians can diagnose concerns correctly and select safe, effective repair or service actions. Earning ASE certification helps technicians demonstrate technical competence to employers and customers—and supports professional growth in the field.

Structure of the ASE Certification Test

The ASE Automobile series for Master Automobile Technician status includes eight separate exams: A1 (Engine Repair), A2 (Automatic Transmission/Transaxle), A3 (Manual Drive Train and Axles), A4 (Suspension and Steering), A5 (Brakes), A6 (Electrical/Electronic Systems), A7 (Heating and Air Conditioning), and A8 (Engine Performance). Each test is computer-based and uses multiple-choice questions built around practical, real-world shop scenarios.

Scoring of the ASE Certification Test

ASE uses a scaled scoring process and reports results as pass/fail. The number of questions and time allowed can vary by test, and certification exams include 10 additional research questions that do not count toward your score. Because research questions are not identified, you should answer every question.

Test Administration

ASE tests are delivered by appointment on a computer at approved testing locations. Depending on the specific test and availability, some exams may also be offered through remote/online proctoring options. Registration and scheduling are completed in advance through ASE’s testing portal.

Test Preparation

Preparing for the ASE Certification Test requires a mix of focused study and practical experience. Start with the official test content areas to understand what is covered, then reinforce learning with targeted practice questions and hands-on troubleshooting. The most effective prep mirrors the exam: verify symptoms, interpret test results, follow a logical diagnostic path, and choose the best next step.

Recognition and Benefits

ASE certification is widely recognized across the automotive service industry. Certified technicians often stand out for hiring and advancement opportunities, and many employers view certification as a reliable indicator of verified skills and professional commitment.

Common names for the ASE A1-A8 Certification Test

The ASE Master Automobile Technician Test is commonly referred to by several names:

- ASE Master Technician Test

- ASE Master Certification Test

- ASE A-Series Test

- ASE Master Auto Tech Test

- ASE Master Automobile Service Test

- ASE Master Mechanic Test

- ASE Master Auto Repair Test

- ASE Master Certification Exam

- ASE Master Automobile Technician Certification Exam

Technical Facts

Test Fast Facts (tl;dr)

- Format: Computer-based, multiple-choice

- Master Auto path: 8 tests (A1–A8)

- Per test: 40–50 scored questions + 10 research questions

- Time: 60–90 minutes (varies by test)

- Scoring: Pass/fail (scaled)

- Where: Prometric test centers (appointment required)

- Certification requirement: Typically 2 years hands-on experience (or approved training + work mix)

- Retakes: Waiting period may apply (often 30 days)

- Results: Posted to your ASE account (often emailed)

Results Scale and Interpretations

ASE exams use a scaled scoring process. Your raw score (how many scored questions you answered correctly) is converted to a scaled result to account for overall test difficulty. Because of this, there isn’t a reliable “percent correct” target you can use across different test versions—focus on mastering the tested tasks and diagnostic process instead.

| Aspect | Details |

|---|---|

| Test Format | Computer-based, multiple-choice |

| Number of Questions | Typically 40–50 scored + 10 research questions (varies by test) |

| Scoring | Pass/fail using a scaled scoring process |

| Test Duration | Typically 60–90 minutes (varies by test) |

| Source: iPREP |

What your score report typically tells you

- Pass/Fail status: Whether you passed that specific test.

- Performance feedback by topic: Many score reports include diagnostic feedback to help you see which content areas were stronger or weaker.

- Use for retakes: If you didn’t pass, use the topic feedback to focus your study plan before scheduling a retest.

If you don’t pass, a waiting period may apply before you can purchase and schedule the same test again (often 30 days).

ASE Certification FAQs

The ASE Certification Test is a professional certification exam administered by the National Institute for Automotive Service Excellence (ASE). It is designed to validate the technical knowledge and skills of automotive service professionals across specific repair and diagnostic areas.

For the Master Automobile Technician path, the A1–A8 tests measure skills across engine repair, automatic transmission/transaxle, manual drive train and axles, suspension and steering, brakes, electrical/electronic systems, heating and air conditioning, and engine performance.

ASE tests are computer-based and multiple-choice. Questions are commonly scenario-based and focus on diagnosis, interpreting test results, and selecting the best repair or next step.

ASE uses a scaled scoring process and reports results as pass/fail. Your raw performance is converted through a scaling method that accounts for overall test difficulty, so there isn’t a single universal “70 = passing” rule you can rely on.

ASE certification is widely recognized in the automotive industry. Many employers use ASE credentials as a benchmark when hiring or promoting because it signals verified skills and professional commitment.

ASE tests are offered during scheduled testing periods throughout the year, and you book an appointment through the ASE/Prometric system. If you don’t pass a test, a waiting period may apply before you can retake it (often 30 days). Always confirm current availability and retest rules in your ASE account.

You can typically take the tests without meeting prerequisites upfront, but to earn ASE certification you generally need relevant hands-on work experience (often two years) or an approved combination of work experience and formal training, depending on your background.

Bring an unexpired, government-issued photo ID and your appointment confirmation details. Personal items such as notes, books, calculators (unless specifically allowed), and electronic devices (including phones) are not permitted in the testing room.

Start with the official test content areas to guide your study plan, then reinforce with practice questions and hands-on diagnostics. Using current, objective-aligned materials is especially important for the A1 and A2 exams effective January 2026.

Results are typically posted to your ASE account after your testing appointment, and you may also receive an email notification. Results are generally not released by phone or to third parties without the candidate’s authorization.

Test Tips

Here are seven practical tips to help you feel confident on test day:

- Arrive early: Give yourself extra time to check in, store items, and settle in before the exam starts.

- Bring the essentials: Bring an unexpired, government-issued photo ID and your appointment confirmation details.

- Pack light: Personal items (notes, books, and electronic devices like phones) aren’t allowed in the testing room, so bring only what you need.

- Read carefully: ASE questions often include small details that change the correct answer—slow down and make sure you’re answering what’s being asked.

- Use elimination: If you’re unsure, cross out clearly wrong options first to improve your odds.

- Don’t get stuck: Flag tough questions, move on, and return if time allows.

- Answer every question: There’s no benefit to leaving items blank—make your best educated guess.

Administration

- Test location: ASE A1–A8 tests are delivered at Prometric test centers (computer-based).

- Scheduling: You register through your ASE account and then book a Prometric appointment. Testing availability is offered in scheduled periods throughout the year and varies by location—check your portal for current dates and open seats.

- Test format: Computer-based, multiple-choice. Each A-test (A1–A8) focuses on a specific area of automotive diagnosis and repair.

- Test materials / personal items: Personal items (notes, books, phones, smart devices, etc.) are not allowed in the testing room. The test center typically provides any scratch materials you’re allowed to use, so you generally don’t need to bring pen/paper.

- Cost: Fees can change. Plan for a registration fee plus a per-test fee when you purchase exams in your ASE account. Advanced-level tests (L1–L3) are typically priced higher than A-tests.

- Retake policy: If you don’t pass, a waiting period may apply before you can purchase/schedule the same test again (often 30 days). Retake limits and rules are managed through your ASE account.

Test Provider

The National Institute for Automotive Service Excellence (ASE), founded in 1972, is a non-profit organization focused on improving the quality of vehicle repair and service. ASE does this by developing industry-supported standards and certifying automotive professionals through testing. ASE credentials are widely recognized across the automotive service industry in the United States.

ASE offers certification exams across multiple specialty areas (including the Automobile series). For the A1–A8 path, ASE delivers testing through Prometric test centers nationwide, allowing candidates to schedule computer-based exams by appointment.

Information Sources

- National Institute for Automotive Service Excellence

- Prometric Test Centers

- Official ASE Education Foundation

Disclaimer – All information and preparation materials on iPREP are created for tutoring purposes. iPREP is not affiliated with the National Institute for Automotive Service Excellence (ASE), the owner of the ASE Certification Test, nor with Prometric or any other organizations mentioned on this page.

Free ASE practice test: Get to know what the ASE Certification Test will be like by practicing with these sample questions:

A1 – Engine Repair Sample Questions

A1 – Question 1 of 5

A customer brings in their car complaining of a rough idle. You notice that the Check Engine Light is on and retrieve a P0302 code. What does this code indicate?

- A problem with the fuel injector

- A misfire in cylinder 3

- A problem with the oxygen sensor

- A misfire in cylinder 2

The correct answer is (D). A P0302 code indicates a misfire in cylinder 2.

Explanation:

- Option (B) is incorrect because a P0303 code would indicate a misfire in cylinder 3.

- Option (C) is incorrect because a problem with the oxygen sensor would trigger a different code, typically starting with P013 or P014.

- Option (A) is incorrect because a problem with the fuel injector would also trigger a different code, typically starting with P02 or P03. However, it’s worth noting that a faulty fuel injector could potentially cause a misfire in a specific cylinder, which might lead to a P0302 code. But the code itself specifically indicates a misfire, not a fuel injector issue.

A1 – Question 2 of 5

A customer’s vehicle has an oil leak. After inspecting the vehicle, you determine that the leak is coming from the area around the oil filter. What is the most likely cause of this leak?

- The oil filter is not tightened properly.

- The oil pan gasket is leaking.

- The valve cover gasket is leaking.

- The head gasket is leaking.

The correct answer is (A). The oil filter is not tightened properly.

Explanation:

- Option (B) is incorrect because an oil pan gasket leak would typically result in oil leaking from the bottom of the engine, not the area around the oil filter.

- Option (C) is incorrect because a valve cover gasket leak would typically result in oil leaking from the top of the engine, not the area around the oil filter.

- Option (D) is incorrect because a head gasket leak could cause oil to mix with coolant, result in white smoke from the exhaust, or cause overheating, but it would not typically cause a leak around the oil filter.

A1 – Question 3 of 5

A customer complains of a squealing noise from the engine compartment that gets worse when the air conditioning is turned on. What is the most likely cause of this noise?

- The air conditioning compressor is failing.

- The serpentine belt is worn or loose.

- The power steering pump is failing.

- The timing belt is worn or loose.

The correct answer is (B). The serpentine belt is worn or loose.

Explanation:

- Option (A) is incorrect because a failing air conditioning compressor would typically make a grinding or rattling noise, not a squealing noise.

- Option (C) is incorrect because a failing power steering pump would typically make a whining noise, especially when turning the steering wheel, not a squealing noise.

- Option (D) is incorrect because a worn or loose timing belt would typically result in a ticking noise coming from inside the engine, not a squealing noise from the engine compartment.

A1 – Question 4 of 5

A customer complains that their car is hard to start in the morning, but once it starts, it runs fine for the rest of the day. What is the most likely cause of this problem?

- The battery is weak.

- The fuel pump is failing.

- The spark plugs are worn out.

- The engine coolant temperature sensor is faulty.

The correct answer is (D). The engine coolant temperature sensor is faulty.

Explanation:

- Option (A) is incorrect because a weak battery would typically cause the car to have trouble starting all the time, not just in the morning.

- Option (B) is incorrect because a failing fuel pump would typically cause the car to have performance issues even after it starts, such as hesitation or stalling.

- Option (C) is incorrect because worn out spark plugs could cause a variety of issues, including hard starting, but these issues would typically not be limited to the morning.

- Option (D) is correct because the engine coolant temperature sensor plays a key role in the engine’s cold start enrichment. If the sensor is faulty and reads the engine temperature as warm when it’s actually cold, the engine control unit (ECU) may not provide enough fuel for a cold start, causing the hard starting issue in the morning. Once the engine is running and warms up, this issue would not affect drivability.

A1 – Question 5 of 5

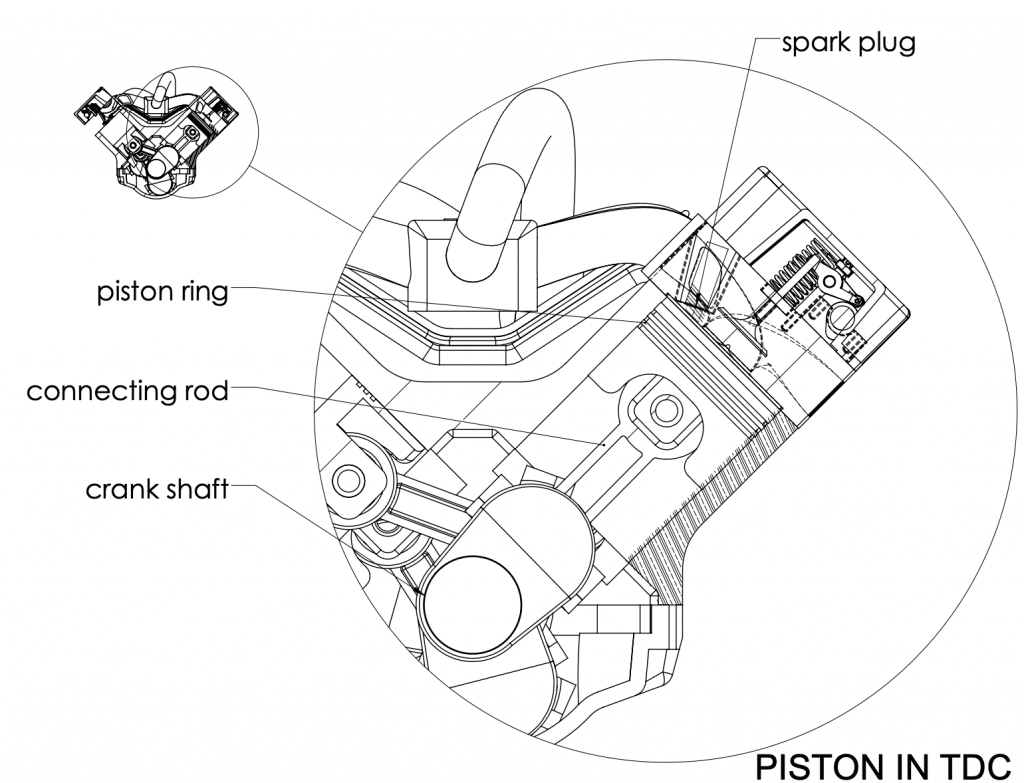

Based on the diagram, which of the following is most likely to cause a loss of compression in this cylinder?

- A worn out connecting rod bearing.

- A broken piston ring.

- A worn out crankshaft bearing.

- A loose spark plug.

The correct answer is (B). A broken piston ring.

Explanation:

- Option (A) is incorrect because a worn out connecting rod bearing would cause a knocking noise and potentially engine damage, but it would not typically cause a loss of compression.

- Option (C) is incorrect because a worn out crankshaft bearing would cause a knocking noise and potentially engine damage, but it would not typically cause a loss of compression.

- Option (D) is incorrect because a loose spark plug could cause a misfire and a loss of power, but it would not typically cause a loss of compression.

- Option (B) is correct because a broken piston ring can cause a loss of compression. The piston rings seal the gap between the piston and the cylinder wall. If a ring is broken, compression can escape past the ring, leading to a loss of compression in the cylinder.

A2 – Automatic Transmission/Transaxle Sample Questions

A2 – Question 1 of 5

A customer complains that their vehicle’s automatic transmission is slipping and the fluid is dark and smells burnt. What is the most likely cause of these symptoms?

- The transmission fluid level is low.

- The transmission fluid needs to be changed.

- The transmission filter is clogged.

- The transmission is overheating.

The correct answer is (D). The transmission is overheating.

Explanation:

- Option (A) is incorrect because while a low transmission fluid level can cause slipping, it would not typically cause the fluid to become dark and smell burnt.

- Option (B) is incorrect because while old transmission fluid can become dark and smell burnt, it would not typically cause the transmission to slip unless it has degraded to the point of causing overheating or other damage.

- Option (C) is incorrect because a clogged transmission filter can cause slipping and other performance issues, but it would not typically cause the fluid to become dark and smell burnt unless it has led to overheating or other damage.

- Option (D) is correct because overheating can cause both slipping and the fluid to become dark and smell burnt. Overheating can be caused by several factors, including low fluid level, old or degraded fluid, a clogged filter, or mechanical issues with the transmission.

A2 – Question 2 of 5

A customer’s vehicle is experiencing delayed shifting and the Check Engine Light is on. You retrieve a P0753 code. What does this code indicate?

- Torque converter clutch solenoid circuit electrical.

- Transmission fluid temperature sensor circuit high input.

- Pressure control solenoid A control circuit range/performance.

- Shift solenoid A electrical fault.

The correct answer is (D). Shift solenoid A electrical fault.

Explanation:

- Option (A) is incorrect because a torque converter clutch solenoid circuit electrical would trigger a different code, typically starting with P074.

- Option (B) is incorrect because a transmission fluid temperature sensor circuit high input would trigger a different code, typically starting with P071.

- Option (C) is incorrect because a pressure control solenoid A control circuit range/performance would trigger a different code, typically starting with P079.

- Option (D) is correct because a P0753 code specifically indicates a shift solenoid A electrical fault. This could cause delayed shifting as the solenoid controls the flow of fluid in the transmission and helps to engage the appropriate gear.

A2 – Question 3 of 5

A customer complains that their vehicle’s automatic transmission is not shifting into overdrive. You notice that the overdrive light is flashing. What is the most likely cause of this problem?

- The overdrive solenoid is faulty.

- The transmission fluid level is low.

- The vehicle speed sensor is faulty.

- The transmission control module is faulty.

The correct answer is (A). The overdrive solenoid is faulty.

Explanation:

- Option (B) is incorrect because while a low transmission fluid level can cause a variety of transmission issues, it would not typically cause the overdrive light to flash.

- Option (C) is incorrect because a faulty vehicle speed sensor could cause shifting issues and other performance problems, but it would not typically cause the overdrive light to flash.

- Option (D) is incorrect because while a faulty transmission control module could cause a variety of transmission issues, including problems with overdrive, it would typically cause other symptoms as well, such as shifting issues in other gears or a failure to shift at all.

- Option (A) is correct because a faulty overdrive solenoid could prevent the transmission from shifting into overdrive and cause the overdrive light to flash. The overdrive solenoid controls the flow of fluid to the overdrive clutch, and if it’s not working properly, the clutch may not engage as it should.

A2 – Question 4 of 5

A customer complains that their vehicle’s automatic transmission is not shifting out of first gear. The fluid level is correct and the fluid is clean. What is the most likely cause of this problem?

- The shift linkage is misadjusted.

- The transmission control module is in “limp mode.”

- The transmission fluid is too thin.

- The torque converter is failing.

The correct answer is (B). The transmission control module is in “limp mode.”

Explanation:

- Option (A) is incorrect because a misadjusted shift linkage would typically cause problems with manual shifting, not automatic shifting.

- Option (C) is incorrect because thin transmission fluid could cause slipping or overheating, but it would not typically prevent the transmission from shifting out of first gear.

- Option (D) is incorrect because a failing torque converter could cause a variety of transmission issues, but it would not typically prevent the transmission from shifting out of first gear.

- Option (B) is correct because when the transmission control module detects a problem that could cause damage to the transmission, it can put the transmission into “limp mode,” which typically limits the transmission to only first gear to prevent further damage.

A2 – Question 5 of 5

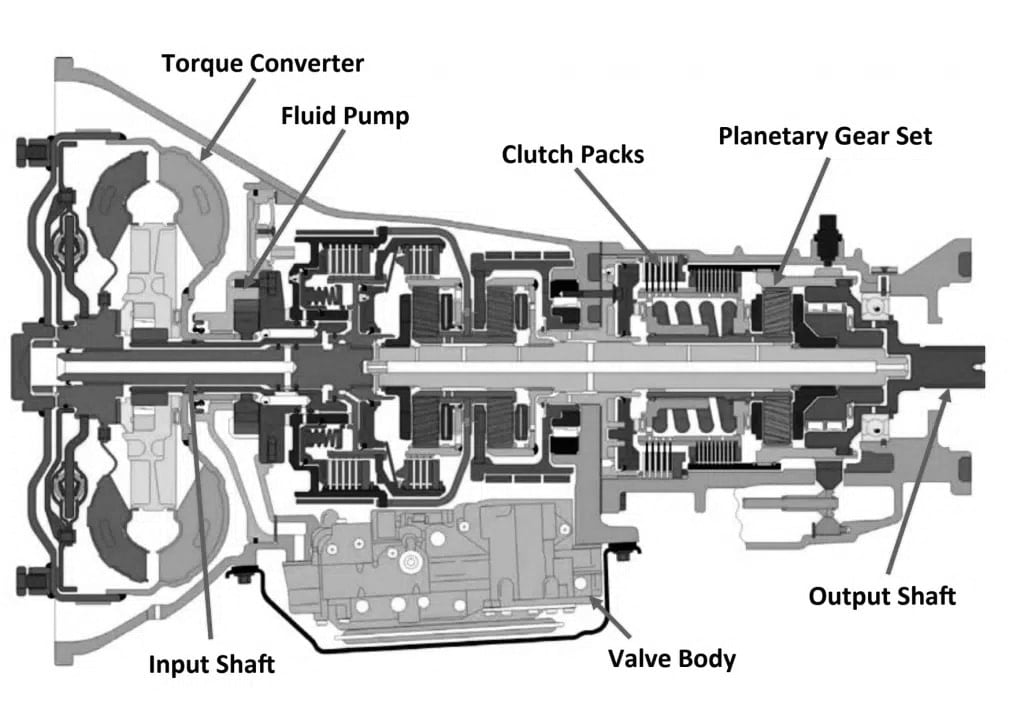

Based on the diagram, which of the following is most likely to cause the transmission to slip when shifting from first to second gear?

- A worn out torque converter.

- A faulty fluid pump.

- A worn out clutch pack for second gear.

- A broken tooth on the planetary gear set.

The correct answer is (C). A worn out clutch pack for second gear.

Explanation:

- Option (A) is incorrect because a worn out torque converter would cause a lack of power or a shuddering sensation, but it would not typically cause the transmission to slip when shifting.

- Option (B) is incorrect because a faulty fluid pump could cause a variety of transmission problems, but it would not typically cause the transmission to slip when shifting.

- Option (D) is incorrect because a broken tooth on the planetary gear set could cause a variety of transmission problems, but it would not typically cause the transmission to slip when shifting.

- Option (C) is correct because a worn out clutch pack for second gear can cause the transmission to slip when shifting from first to second gear. The clutch packs are responsible for engaging and disengaging the gears. If the clutch pack for second gear is worn out, it may not fully engage when the transmission shifts into second gear, causing the transmission to slip.

A3 – Manual Drive Train and Axles Sample Questions

A3 – Question 1 of 5

A customer complains of a grinding noise from the rear of their rear-wheel-drive vehicle when making turns. The noise is not present when driving straight. What is the most likely cause of this noise?

- The rear differential fluid is low or contaminated.

- The rear wheel bearings are worn.

- The rear brake pads are worn.

- The rear drive shaft U-joints are worn.

The correct answer is (A). The rear differential fluid is low or contaminated.

Explanation:

- Option (B) is incorrect because worn wheel bearings would typically cause a humming or growling noise that gets louder with speed, not a grinding noise when turning.

- Option (C) is incorrect because worn brake pads would typically cause a squealing or grinding noise when braking, not when turning.

- Option (D) is incorrect because worn U-joints would typically cause a clunking noise when accelerating or decelerating, not a grinding noise when turning.

- Option (A) is correct because the rear differential allows the rear wheels to rotate at different speeds when turning. If the fluid is low or contaminated, it can cause a grinding noise when the wheels are rotating at different speeds, such as when making turns.

A3 – Question 2 of 5

A customer complains that their vehicle’s clutch pedal feels soft and the vehicle is hard to shift. The clutch fluid level is correct and the fluid is clean. What is the most likely cause of this problem?

- The clutch disc is worn.

- The clutch master cylinder is failing.

- The transmission synchronizers are worn.

- The clutch cable is stretched.

The correct answer is (B). The clutch master cylinder is failing.

Explanation:

- Option (A) is incorrect because a worn clutch disc would typically cause slipping, not a soft pedal feel or difficulty shifting.

- Option (C) is incorrect because worn transmission synchronizers would typically cause grinding when shifting, not a soft pedal feel.

- Option (D) is incorrect because a stretched clutch cable would typically cause a high clutch pedal engagement point, not a soft pedal feel.

- Option (B) is correct because the clutch master cylinder generates the hydraulic pressure needed to disengage the clutch when the pedal is pressed. If it’s failing, it may not generate enough pressure, resulting in a soft pedal feel and difficulty shifting.

A3 – Question 3 of 5

A customer complains that their vehicle’s manual transmission pops out of first gear into neutral on its own. The transmission fluid level is correct and the fluid is clean. What is the most likely cause of this problem?

- The first gear synchronizer is worn.

- The clutch disc is worn.

- The transmission mount is broken.

- The shift linkage is misadjusted.

The correct answer is (A). The first gear synchronizer is worn.

Explanation:

- Option (B) is incorrect because a worn clutch disc would typically cause slipping, not the transmission popping out of gear.

- Option (C) is incorrect because a broken transmission mount could cause a variety of issues, including noise and vibration, but it would not typically cause the transmission to pop out of gear.

- Option (D) is incorrect because a misadjusted shift linkage could cause difficulty getting into gear, but it would not typically cause the transmission to pop out of gear.

- Option (A) is correct because the synchronizers in a manual transmission help the gears to mesh smoothly. If a synchronizer is worn, it may not hold the gears together properly, causing the transmission to pop out of gear.

A3 – Question 4 of 5

A customer complains that their vehicle’s manual transmission is hard to shift into all gears. The clutch pedal feels normal and the vehicle does not grind gears when shifting. What is the most likely cause of this problem?

- The clutch disc is worn.

- The transmission fluid is low or contaminated.

- The shift linkage is misadjusted.

- The transmission mount is broken.

The correct answer is (C). The shift linkage is misadjusted.

Explanation:

- Option (A) is incorrect because a worn clutch disc would typically cause slipping or difficulty disengaging the clutch, not difficulty shifting into all gears.

- Option (B) is incorrect because low or contaminated transmission fluid would typically cause noisy operation or difficulty shifting into specific gears, not difficulty shifting into all gears.

- Option (D) is incorrect because a broken transmission mount could cause a variety of issues, including noise and vibration, but it would not typically cause difficulty shifting into all gears.

- Option (C) is correct because the shift linkage connects the gear shift to the transmission. If it’s misadjusted, it can cause difficulty shifting into all gears. The fact that the problem occurs with all gears and there are no other symptoms like grinding or a strange pedal feel suggests a problem with the linkage rather than the transmission or clutch itself.

A3 – Question 5 of 5

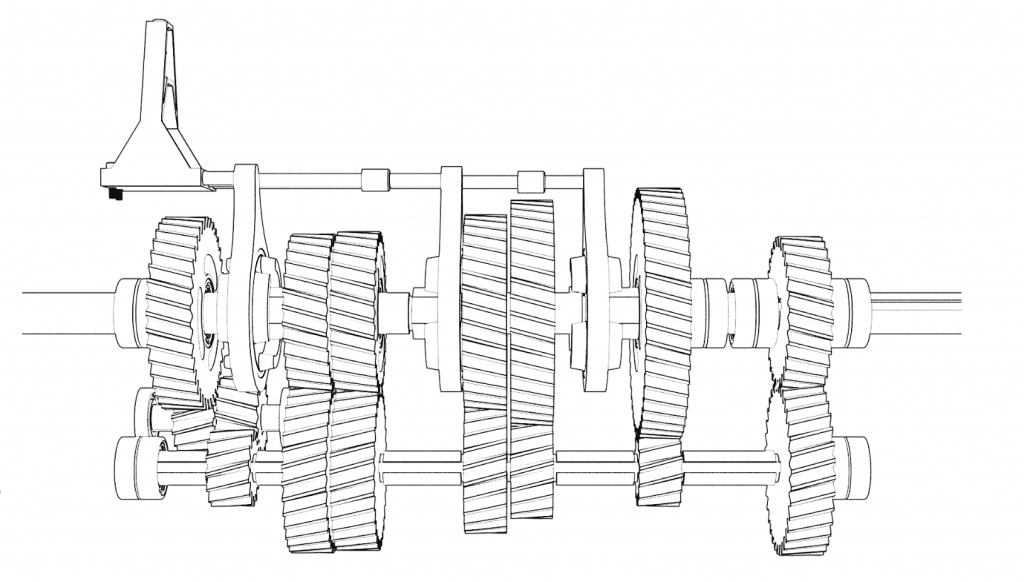

Based on the diagram, which of the following is most likely to cause the transmission to grind when shifting from third to fourth gear?

- A worn out input shaft bearing.

- A faulty shift fork for fourth gear.

- A worn out synchronizer for fourth gear.

- A broken tooth on the third gear.

The correct answer is (C). A worn out synchronizer for fourth gear.

Explanation:

- Option (A) is incorrect because a worn out input shaft bearing would cause a whining or growling noise, but it would not typically cause the transmission to grind when shifting.

- Option (B) is incorrect because a faulty shift fork could cause difficulty shifting into or out of a particular gear, but it would not typically cause the transmission to grind when shifting.

- Option (D) is incorrect because a broken tooth on the third gear could cause a variety of transmission problems, but it would not typically cause the transmission to grind when shifting.

- Option (C) is correct because a worn out synchronizer for fourth gear can cause the transmission to grind when shifting from third to fourth gear. The synchronizers are responsible for matching the speed of the gears before they engage. If the synchronizer for fourth gear is worn out, it may not fully synchronize the gears when the transmission shifts into fourth gear, causing the transmission to grind.

A4 – Suspension and Steering Sample Questions

A4 – Question 1 of 5

A customer complains that their vehicle pulls to the right when braking. The brakes do not make any noise and the brake pedal feels normal. What is the most likely cause of this problem?

- The left front brake pads are worn.

- The brake fluid is contaminated.

- The vehicle’s alignment is off.

- The right front brake caliper is sticking.

The correct answer is (D). The right front brake caliper is sticking.

Explanation:

- Option (A) is incorrect because worn brake pads on one side could cause a pull to the opposite side when braking, but there would typically be other symptoms as well, such as noise or a low brake pedal.

- Option (B) is incorrect because contaminated brake fluid would typically cause a spongy brake pedal feel or reduced braking performance, not a pull to one side when braking.

- Option (C) is incorrect because while an off alignment can cause a vehicle to pull to one side, it would typically do so all the time, not just when braking.

- Option (D) is correct because a sticking brake caliper on one side can cause the vehicle to pull to that side when braking. The caliper may not be releasing properly after the brake is applied, causing more braking force on that side and pulling the vehicle in that direction.

A4 – Question 2 of 5

A customer complains that their vehicle’s steering wheel shakes when driving at highway speeds. The vehicle does not pull to one side and the tires are in good condition. What is the most likely cause of this problem?

- The wheels are out of balance.

- The power steering pump is failing.

- The vehicle’s alignment is off.

- The steering gear is loose.

The correct answer is (A). The wheels are out of balance.

Explanation:

- Option (B) is incorrect because a failing power steering pump would typically cause difficulty steering or noise when turning the steering wheel, not a shake at highway speeds.

- Option (C) is incorrect because while an off alignment can cause a variety of issues, it would not typically cause the steering wheel to shake at highway speeds.

- Option (D) is incorrect because a loose steering gear could cause loose or sloppy steering, but it would not typically cause the steering wheel to shake at highway speeds.

- Option (A) is correct because wheels that are out of balance can cause the steering wheel to shake at certain speeds, typically around 50-70 mph. The imbalance causes the wheels to wobble as they rotate, which can be felt through the steering wheel.

A4 – Question 3 of 5

A customer complains that their vehicle’s steering feels loose and the vehicle wanders on the road. The tires are in good condition and the vehicle does not pull to one side. What is the most likely cause of this problem?

- The power steering fluid is low.

- The vehicle’s alignment is off.

- The steering linkage is worn.

- The brake rotors are warped.

The correct answer is (C). The steering linkage is worn.

Explanation:

- Option (A) is incorrect because low power steering fluid would typically cause difficulty steering or noise when turning the steering wheel, not loose steering or wandering.

- Option (B) is incorrect because while an off alignment can cause a variety of issues, it would not typically cause loose steering or wandering.

- Option (D) is incorrect because warped brake rotors would typically cause a pulsation in the brake pedal or a shake in the steering wheel when braking, not loose steering or wandering.

- Option (C) is correct because worn steering linkage can cause loose steering and wandering. The linkage connects the steering wheel to the wheels, and if it’s worn, it can allow the wheels to move independently of the steering wheel, resulting in a loose feel and wandering.

A4 – Question 4 of 5

A customer complains that their vehicle’s steering wheel is hard to turn. The vehicle does not make any noise when turning and the steering does not feel loose. What is the most likely cause of this problem?

- The power steering pump is failing.

- The wheels are out of balance.

- The steering gear is loose.

- The vehicle’s alignment is off.

The correct answer is (A). The power steering pump is failing.

Explanation:

- Option (B) is incorrect because wheels that are out of balance would typically cause the steering wheel to shake at certain speeds, not make it hard to turn.

- Option (C) is incorrect because a loose steering gear could cause loose or sloppy steering, but it would not typically make the steering wheel hard to turn.

- Option (D) is incorrect because while an off alignment can cause a variety of issues, it would not typically make the steering wheel hard to turn.

- Option (A) is correct because the power steering pump provides the hydraulic pressure needed to assist the steering. If it’s failing, it may not provide enough pressure, making the steering wheel hard to turn.

A4 – Question 5 of 5

Based on the diagram, which of the following is most likely to cause excessive body roll during cornering?

- A worn out control arm bushing.

- A faulty strut assembly.

- A worn out sway bar link.

- A loose tie rod end.

The correct answer is (C). A worn out sway bar link.

Explanation:

- Option (A) is incorrect because a worn out control arm bushing could cause a variety of suspension problems, including poor handling and uneven tire wear, but it would not typically cause excessive body roll during cornering.

- Option (B) is incorrect because a faulty strut assembly could cause a variety of suspension problems, including poor ride quality and uneven tire wear, but it would not typically cause excessive body roll during cornering.

- Option (D) is incorrect because a loose tie rod end could cause a variety of steering problems, including poor steering response and uneven tire wear, but it would not typically cause excessive body roll during cornering.

- Option (C) is correct because a worn out sway bar link can cause excessive body roll during cornering. The sway bar helps to reduce body roll during cornering. If the link that connects the sway bar to the suspension is worn out, it may not effectively control body roll.

A5 – Brakes Sample Questions

A5 – Question 1 of 5

A customer complains that their vehicle’s brakes squeal when applied. The brake pedal feels normal and the vehicle does not pull to one side when braking. What is the most likely cause of this problem?

- The brake pads are worn.

- The brake fluid is contaminated.

- The brake calipers are sticking.

- The brake rotors are warped.

The correct answer is (A). The brake pads are worn.

Explanation:

- Option (B) is incorrect because contaminated brake fluid would typically cause a spongy brake pedal feel or reduced braking performance, not squealing brakes.

- Option (C) is incorrect because sticking brake calipers could cause the vehicle to pull to one side when braking or cause the brakes to drag, not squeal.

- Option (D) is incorrect because warped brake rotors would typically cause a pulsation in the brake pedal or a shake in the steering wheel when braking, not squealing brakes.

- Option (A) is correct because worn brake pads can cause a squealing noise when applied. Many brake pads have a wear indicator that makes a squealing noise when the pads are worn to a certain point.

A5 – Question 2 of 5

A customer complains that their vehicle’s brake pedal feels spongy. The brakes do not make any noise and the vehicle does not pull to one side when braking. What is the most likely cause of this problem?

- The brake fluid is contaminated.

- The brake pads are worn.

- The brake calipers are sticking.

- The brake rotors are warped.

The correct answer is (A). The brake fluid is contaminated.

Explanation:

- Option (B) is incorrect because worn brake pads would typically cause a low brake pedal or a squealing noise, not a spongy pedal feel.

- Option (C) is incorrect because sticking brake calipers could cause the vehicle to pull to one side when braking or cause the brakes to drag, not a spongy pedal feel.

- Option (D) is incorrect because warped brake rotors would typically cause a pulsation in the brake pedal or a shake in the steering wheel when braking, not a spongy pedal feel.

- Option (A) is correct because contaminated brake fluid can cause a spongy brake pedal feel. If the fluid is contaminated with water or air, it can compress when the brakes are applied, resulting in a spongy feel.

A5 – Question 3 of 5

A customer complains that their vehicle’s brakes are dragging. The brake pedal feels normal and the brakes do not make any noise. What is the most likely cause of this problem?

- The brake rotors are warped.

- The brake calipers are sticking.

- The brake fluid is contaminated.

- The brake pads are worn.

The correct answer is (B). The brake calipers are sticking.

Explanation:

- Option (A) is incorrect because warped brake rotors would typically cause a pulsation in the brake pedal or a shake in the steering wheel when braking, not dragging brakes.

- Option (C) is incorrect because contaminated brake fluid would typically cause a spongy brake pedal feel or reduced braking performance, not dragging brakes.

- Option (D) is incorrect because worn brake pads would typically cause a low brake pedal or a squealing noise, not dragging brakes.

- Option (B) is correct because sticking brake calipers can cause the brakes to drag. The caliper may not be releasing properly after the brake is applied, causing the brakes to continue to apply pressure even when the pedal is released.

A5 – Question 4 of 5

A customer complains that their vehicle’s brake pedal pulsates when applied. The brakes do not make any noise and the vehicle does not pull to one side when braking. What is the most likely cause of this problem?

- The brake pads are worn.

- The brake fluid is contaminated.

- The brake calipers are sticking.

- The brake rotors are warped.

The correct answer is (D). The brake rotors are warped.

Explanation:

- Option (A) is incorrect because worn brake pads would typically cause a low brake pedal or a squealing noise, not a pulsating pedal.

- Option (B) is incorrect because contaminated brake fluid would typically cause a spongy brake pedal feel or reduced braking performance, not a pulsating pedal.

- Option (C) is incorrect because sticking brake calipers could cause the vehicle to pull to one side when braking or cause the brakes to drag, not a pulsating pedal.

- Option (D) is correct because warped brake rotors can cause the brake pedal to pulsate when applied. The uneven surface of the rotor causes the brake pads to move in and out as they pass over the high and low spots, resulting in a pulsation in the pedal.

A5 – Question 5 of 5

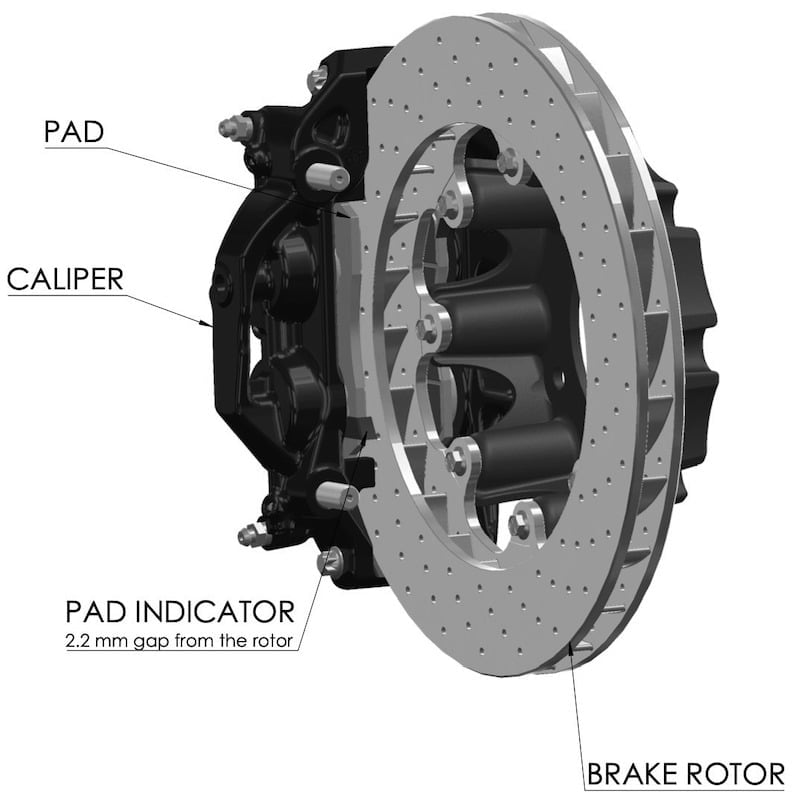

Based on the diagram, which of the following symptoms is most likely to be experienced by the driver when the brake pads are this worn?

- A high-pitched squealing noise when braking.

- A pulsating brake pedal.

- Brake fluid leaking onto the ground.

- A grinding noise when turning the steering wheel.

The correct answer is A. A high-pitched squealing noise when braking.

Explanation:

- Option A is correct because the brake pad wear indicator is designed to produce a high-pitched squealing noise when the brake pads are nearing the end of their service life. This noise serves as an audible warning to the driver that the brake pads need replacement.

- Option B is incorrect because a pulsating brake pedal is typically caused by a warped brake rotor, not worn brake pads.

- Option C is incorrect because brake fluid leaking onto the ground indicates a problem with the brake hydraulic system, not the brake pads.

- Option D is incorrect because a grinding noise when turning the steering wheel is more related to issues with the steering or suspension system, not the brake pads.

A6 – Electrical/Electronic Systems Sample Questions

A6 – Question 1 of 5

A customer complains that their vehicle’s battery keeps dying. The alternator has been tested and is working properly. The vehicle does not have any aftermarket accessories installed. What is the most likely cause of this problem?

- The battery is old and needs to be replaced.

- The vehicle has a short circuit.

- The vehicle’s ignition switch is faulty.

- The vehicle’s starter motor is drawing too much current.

The correct answer is (A). The battery is old and needs to be replaced.

Explanation:

- Option (B) is incorrect because a short circuit would typically cause a blown fuse or other electrical problems, not a dying battery.

- Option (C) is incorrect because a faulty ignition switch could cause a variety of issues, including a no-start condition, but it would not typically cause a dying battery.

- Option (D) is incorrect because a starter motor drawing too much current could cause a slow cranking condition or a no-start condition, but it would not typically cause a dying battery.

- Option (A) is correct because an old battery can lose its ability to hold a charge, resulting in a dying battery. If the alternator is working properly and there are no other electrical problems, the battery itself is the most likely cause.

A6 – Question 2 of 5

A customer complains that their vehicle’s headlights dim and brighten intermittently. The vehicle’s battery and alternator have been tested and are working properly. What is the most likely cause of this problem?

- The vehicle’s headlight switch is faulty.

- The vehicle’s battery cables are loose.

- The vehicle’s alternator belt is slipping.

- The vehicle’s ignition switch is faulty.

The correct answer is (B). The vehicle’s battery cables are loose.

Explanation:

- Option (A) is incorrect because a faulty headlight switch could cause the headlights to not work at all, but it would not typically cause them to dim and brighten intermittently.

- Option (C) is incorrect because a slipping alternator belt could cause the alternator to not charge properly, but if the alternator has been tested and is working properly, this is not the cause.

- Option (D) is incorrect because a faulty ignition switch could cause a variety of issues, including a no-start condition, but it would not typically cause the headlights to dim and brighten.

- Option (B) is correct because loose battery cables can cause intermittent electrical problems, including headlights that dim and brighten. The loose connection can cause the voltage to the headlights to fluctuate, resulting in the dimming and brightening.

A6 – Question 3 of 5

A customer complains that their vehicle’s interior lights do not work. The fuses have been checked and are not blown. The vehicle does not have any other electrical problems. What is the most likely cause of this problem?

- The vehicle’s battery is dead.

- The vehicle’s light switch is faulty.

- The vehicle’s alternator is not charging properly.

- The vehicle’s interior light bulbs are burnt out.

The correct answer is (D). The vehicle’s interior light bulbs are burnt out.

Explanation:

- Option (A) is incorrect because a dead battery would typically cause the vehicle to not start, not just the interior lights to not work.

- Option (C) is incorrect because an alternator not charging properly would typically cause the battery to die or other electrical problems, not just the interior lights to not work.

- Option (B) is incorrect because a faulty light switch could cause the interior lights to not turn on, but if all the interior lights are not working, it’s more likely that the bulbs are the problem.

- Option (D) is correct because if all the interior lights are not working and the fuses are not blown, it’s likely that the bulbs are burnt out. It’s possible for multiple bulbs to burn out at the same time, especially if they were all installed at the same time.

A6 – Question 4 of 5

A customer complains that their vehicle’s turn signals do not work. The fuses have been checked and are not blown. The vehicle does not have any other electrical problems. What is the most likely cause of this problem?

- The vehicle’s turn signal switch is faulty.

- The vehicle’s turn signal relay is faulty.

- The vehicle’s turn signal bulbs are burnt out.

- The vehicle’s battery is dead.

The correct answer is (B). The vehicle’s turn signal relay is faulty.

Explanation:

- Option (A) is incorrect because a faulty turn signal switch could cause the turn signals to not work, but it would typically affect only one side (left or right), not both.

- Option (C) is incorrect because while burnt out bulbs could cause the turn signals to not work, it’s unlikely that all the turn signal bulbs would burn out at the same time.

- Option (D) is incorrect because a dead battery would typically cause the vehicle to not start, not just the turn signals to not work.

- Option (B) is correct because a faulty turn signal relay can cause the turn signals to not work. The relay controls the on-off flashing of the turn signals, and if it’s faulty, it can prevent the turn signals from working at all.

A6 – Question 5 of 5

Based on the image, which of the following is the most probable cause for one headlight appearing dimmer?

- A faulty turn signal relay.

- A corroded ground connection for the dim headlight.

- A malfunctioning brake light switch.

- A blown fuse for the taillights.

The correct answer is B. A corroded ground connection for the dim headlight.

Explanation:

- Option A is incorrect because the turn signal relay wouldn’t affect the brightness of the headlights.

- Option B is correct because a corroded ground connection can reduce the current flow to the headlight, making it appear dimmer.

- Option C is incorrect because the brake light switch wouldn’t affect the headlights.

- Option D is incorrect because a blown fuse for the taillights wouldn’t cause one headlight to appear dimmer.

A7 – Heating and Air Conditioning Sample Questions

A7 – Question 1 of 5

A customer complains that their vehicle’s air conditioning is not cooling properly. The A/C compressor has been tested and is working properly. The vehicle does not have any other issues. What is the most likely cause of this problem?

- The vehicle’s A/C system is low on refrigerant.

- The vehicle’s A/C compressor clutch is faulty.

- The vehicle’s A/C condenser is blocked.

- The vehicle’s A/C system has a leak.

The correct answer is (A). The vehicle’s A/C system is low on refrigerant.

Explanation:

- Option (B) is incorrect because a faulty A/C compressor clutch would typically prevent the compressor from operating, but the compressor has been tested and is working properly.

- Option (C) is incorrect because a blocked A/C condenser could cause the A/C system to not cool properly, but it would typically cause other issues as well, such as overheating.

- Option (D) is incorrect because while an A/C system leak could cause the system to not cool properly, it would typically result in a loss of refrigerant, which is covered by option (A).

- Option (A) is correct because if the A/C system is low on refrigerant, it will not cool properly. The refrigerant is what carries the heat away from the inside of the vehicle, so if there’s not enough of it, the system won’t be able to cool effectively.

A7 – Question 2 of 5

A customer complains that their vehicle’s heater is not working properly. The engine is reaching normal operating temperature and the vehicle does not have any other issues. What is the most likely cause of this problem?

- The vehicle’s thermostat is stuck open.

- The vehicle’s heater core is blocked.

- The vehicle’s coolant level is low.

- The vehicle’s blower motor is faulty.

The correct answer is (B). The vehicle’s heater core is blocked.

Explanation:

- Option (A) is incorrect because a thermostat stuck open would typically prevent the engine from reaching normal operating temperature, but the engine is reaching normal temperature in this case.

- Option (C) is incorrect because a low coolant level could cause the heater to not work properly, but it would typically cause other issues as well, such as overheating.

- Option (D) is incorrect because a faulty blower motor could prevent the heater from working, but it would typically cause the heater to not blow air at all, not just to not work properly.

- Option (B) is correct because a blocked heater core can prevent the heater from working properly. The heater core is like a small radiator that the coolant flows through. If it’s blocked, the hot coolant can’t flow through it to provide heat to the interior of the vehicle.

A7 – Question 3 of 5

A customer complains that their vehicle’s defroster is not clearing the windshield properly. The vehicle’s heater is working properly and the vehicle does not have any other issues. What is the most likely cause of this problem?

- The vehicle’s windshield is dirty on the inside.

- The vehicle’s A/C system is not working properly.

- The vehicle’s defroster vent is blocked.

- The vehicle’s blower motor is faulty.

The correct answer is (C). The vehicle’s defroster vent is blocked.

Explanation:

- Option (A) is incorrect because while a dirty windshield can make it harder for the defroster to clear the windshield, it would not typically prevent the defroster from working properly.

- Option (B) is incorrect because while a malfunctioning A/C system could affect the defroster’s ability to clear the windshield, the customer has not reported any issues with the A/C system.

- Option (D) is incorrect because a faulty blower motor could prevent the defroster from working, but it would typically cause the defroster to not blow air at all, not just to not work properly.

- Option (C) is correct because a blocked defroster vent can prevent the defroster from clearing the windshield properly. The defroster works by blowing air over the windshield to remove condensation. If the vent is blocked, the air can’t reach the windshield to do its job.

A7 – Question 4 of 5

A customer complains that their vehicle’s air conditioning is not cooling as well as it used to. The A/C compressor is engaging and the blower motor is working properly. What is the most likely cause of this problem?

- The vehicle’s A/C system is low on refrigerant.

- The vehicle’s A/C condenser fan is not working.

- The vehicle’s cabin air filter is clogged.

- The vehicle’s A/C compressor clutch is slipping.

The correct answer is (A). The vehicle’s A/C system is low on refrigerant.

Explanation:

- Option (B) is incorrect because a non-working A/C condenser fan would typically cause the A/C system to not cool at all, especially at idle or low speeds.

- Option (C) is incorrect because a clogged cabin air filter could reduce the airflow from the vents, but it would not typically cause the A/C to not cool as well.

- Option (D) is incorrect because a slipping A/C compressor clutch would typically prevent the compressor from engaging, but the compressor is engaging in this case.

- Option (A) is correct because if the A/C system is low on refrigerant, it will not cool as well as it used to. The refrigerant is what carries the heat away from the inside of the vehicle, so if there’s not enough of it, the system won’t be able to cool effectively.

A7 – Question 5 of 5

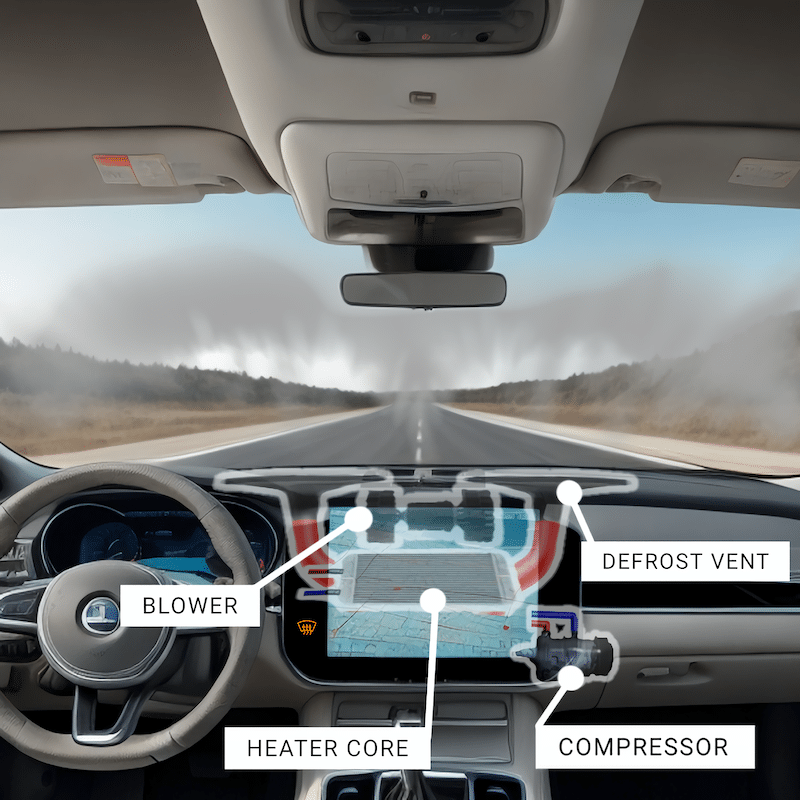

Based on the diagram, which component failure is most likely causing the ineffective defrosting?

- A malfunctioning A/C compressor.

- A clogged cabin air filter.

- A faulty blower motor.

- A leaking heater core.

The correct answer is A. A malfunctioning A/C compressor.

Explanation:

- Option A is correct because the A/C compressor plays a vital role in the defrosting process by removing moisture from the air. If it’s malfunctioning, the system won’t defrost effectively.

- Option B is incorrect because while a clogged cabin air filter can reduce airflow, it wouldn’t directly affect the defrosting process.

- Option C is incorrect because a faulty blower motor would prevent air from blowing, but the diagram suggests the system is turned on.

- Option D is incorrect because a leaking heater core would typically cause a sweet smell and fogging inside the vehicle, not ineffective defrosting.

A8 – Engine Performance Sample Questions

A8 – Question 1 of 5

A customer complains that their vehicle’s Check Engine Light (CEL) is on. The vehicle is running rough and has poor fuel economy. A scan tool reveals a code P0171 – System Too Lean (Bank 1). What is the most likely cause of this problem?

- The vehicle’s fuel pump is failing.

- The vehicle’s oxygen sensor (Bank 1, Sensor 1) is faulty.

- The vehicle’s mass air flow (MAF) sensor is dirty or faulty.

- The vehicle’s spark plugs are worn out.

The correct answer is (C). The vehicle’s mass air flow (MAF) sensor is dirty or faulty.

Explanation:

- Option (A) is incorrect because a failing fuel pump would typically cause a lack of power or a no-start condition, not a lean condition.

- Option (B) is incorrect because while a faulty oxygen sensor could cause a lean condition, it would typically set a specific oxygen sensor code, not a system lean code.

- Option (D) is incorrect because worn out spark plugs could cause a misfire or rough running, but they would not typically cause a lean condition.

- Option (C) is correct because a dirty or faulty MAF sensor can cause a lean condition. The MAF sensor measures the amount of air entering the engine. If it’s dirty or faulty, it can under-report the amount of air, causing the engine to run lean.

A8 – Question 2 of 5

A customer complains that their vehicle’s Check Engine Light (CEL) is on. The vehicle is running fine and does not have any noticeable issues. A scan tool reveals a code P0420 – Catalyst System Efficiency Below Threshold (Bank 1). What is the most likely cause of this problem?

- The vehicle’s catalytic converter (Bank 1) is failing.

- The vehicle’s oxygen sensor (Bank 1, Sensor 2) is faulty.

- The vehicle’s fuel injectors are clogged.

- The vehicle’s mass air flow (MAF) sensor is dirty or faulty.

The correct answer is (A). The vehicle’s catalytic converter (Bank 1) is failing.

Explanation:

- Option (B) is incorrect because while a faulty oxygen sensor could cause a P0420 code, it would typically set a specific oxygen sensor code, not a catalyst efficiency code.

- Option (C) is incorrect because clogged fuel injectors could cause a variety of issues, including misfires and poor fuel economy, but they would not typically cause a catalyst efficiency code.

- Option (D) is incorrect because a dirty or faulty MAF sensor could cause a variety of issues, including lean or rich conditions, but it would not typically cause a catalyst efficiency code.

- Option (A) is correct because a failing catalytic converter can cause a P0420 code. The catalytic converter is responsible for reducing harmful emissions. If it’s not working efficiently, it can set a P0420 code.

A8 – Question 3 of 5